Environmental protection calcium zinc solid compound stabilizer

Environmental protection calcium zinc solid compound stabilizer

Products

Products

Competitive advantage

Competitive advantage

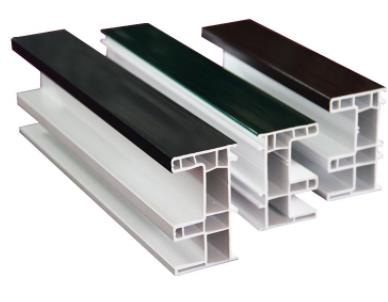

⚫PVC special non-toxic heat stabilizer

⚫ does not contain lead, tin and other toxic heavy metal elements

⚫ substitute lead salt stabilizer.

⚫ has high thermal stability

Product advantage

Product advantage

⚫ has strong optical stability

The product has no obvious discoloration after more than 3 months of uv lamp irradiation experiment, especially for purple, brown, orange color is more obvious stability, overcome the shortcomings of lead salt stabilizer.

⚫ cost-effective

Product performance can completely replace imported similar products; The sales price of the product is 30% lower than that of similar foreign products

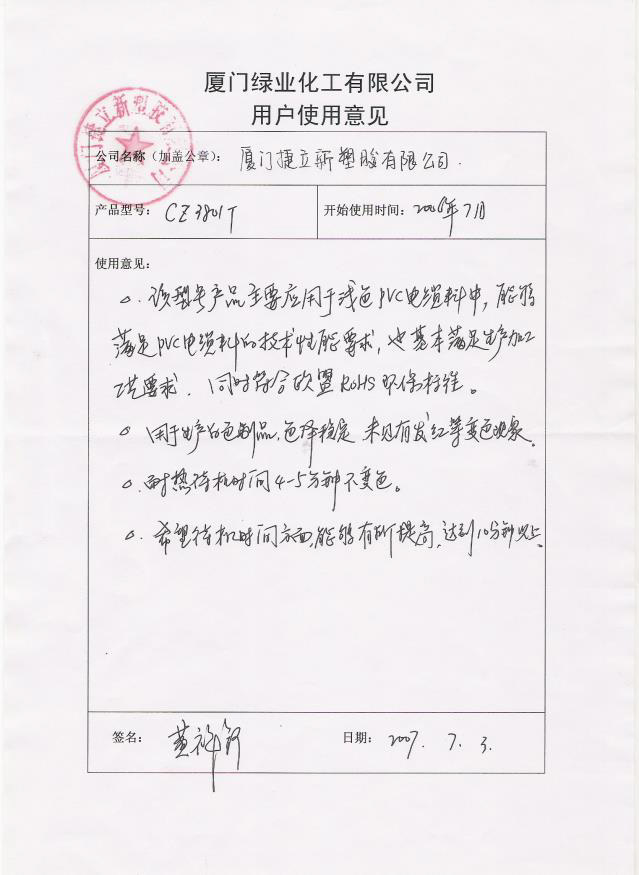

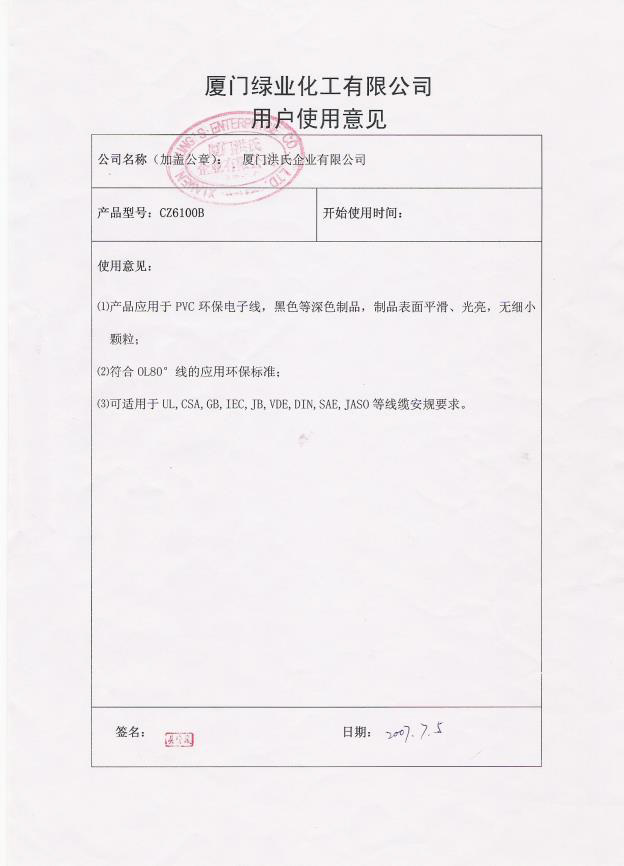

User Opinions

User Opinions

Environmental protection zinc magnesium aluminum solid compound stabilizer after more than ten years of use and verification, has been recognized and used by many customers at home and abroad, product quality is stable and reliable, become a well-known brand stabilizer industry.

Technical indicators

Technical indicators

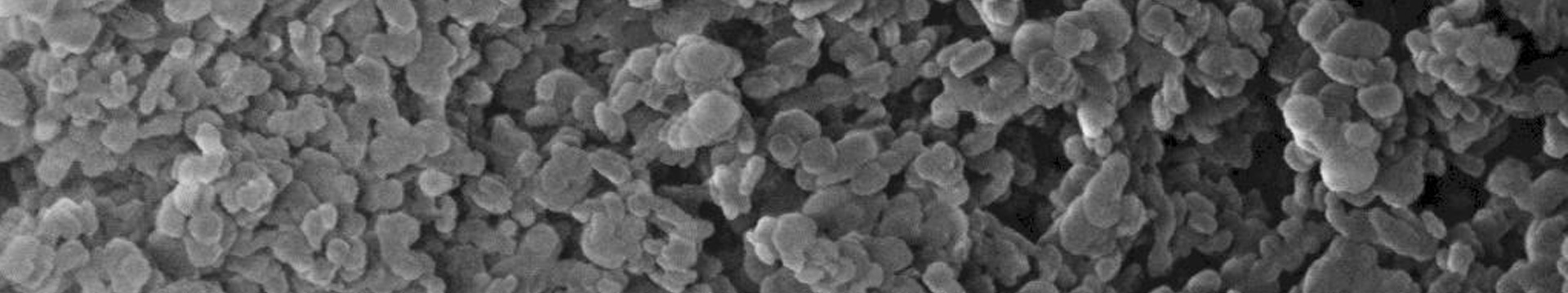

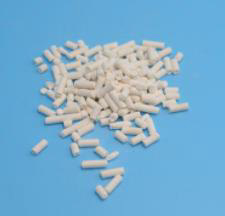

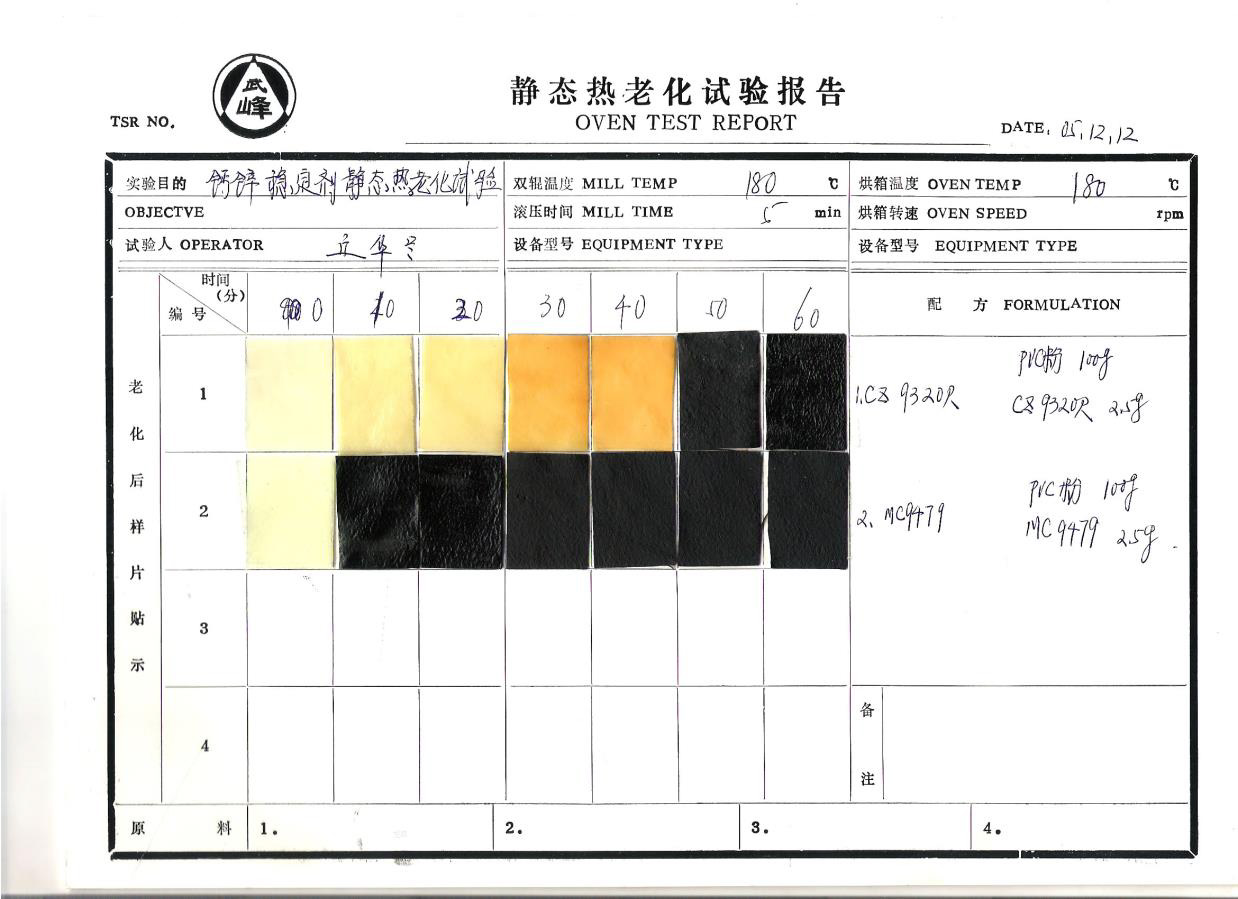

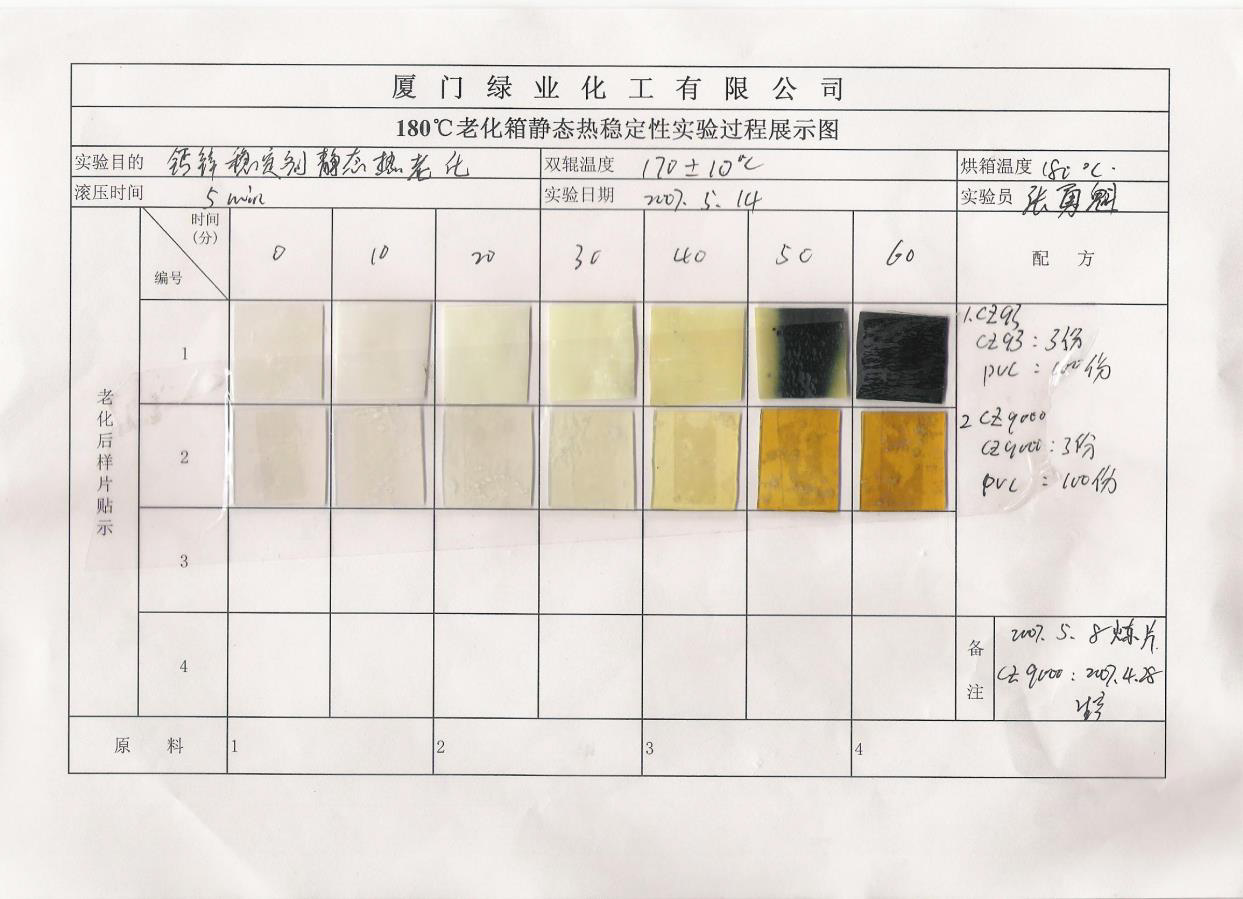

The main physical property of the product is CZ9000

The actual ingredient composition and raw material dosage of stabilizer are the same, and the physical property data of stabilizer will be different when it is used in different products. Necessary adjustments should be made when stabilizer is used in different products. This product is white free flowing powder, compared with liquid or paste calcium zinc compound stabilizer used in the domestic market, it has the advantages of easy packaging, accurate measurement and simple operation, and helps to solve the phenomenon of precipitation, migration and frost spraying of PVC products. ⚫ This product refers to the internationally accepted test method iso182/1 for the thermal stability time of the sample after PVC plasticizingThe time reached 40 minutes, more than the German Bear MC9479 and The Japanese Samichi CZ93, CZ78 and other similar products. ⚫ This product does not contain lead, cadmium, mercury, chromium, VI and other heavy metals. After long-term tracking test by international testing agency SGS, it fully conforms to the ROHS environmental protection standard implemented by the European Union on July 1, 2006. |

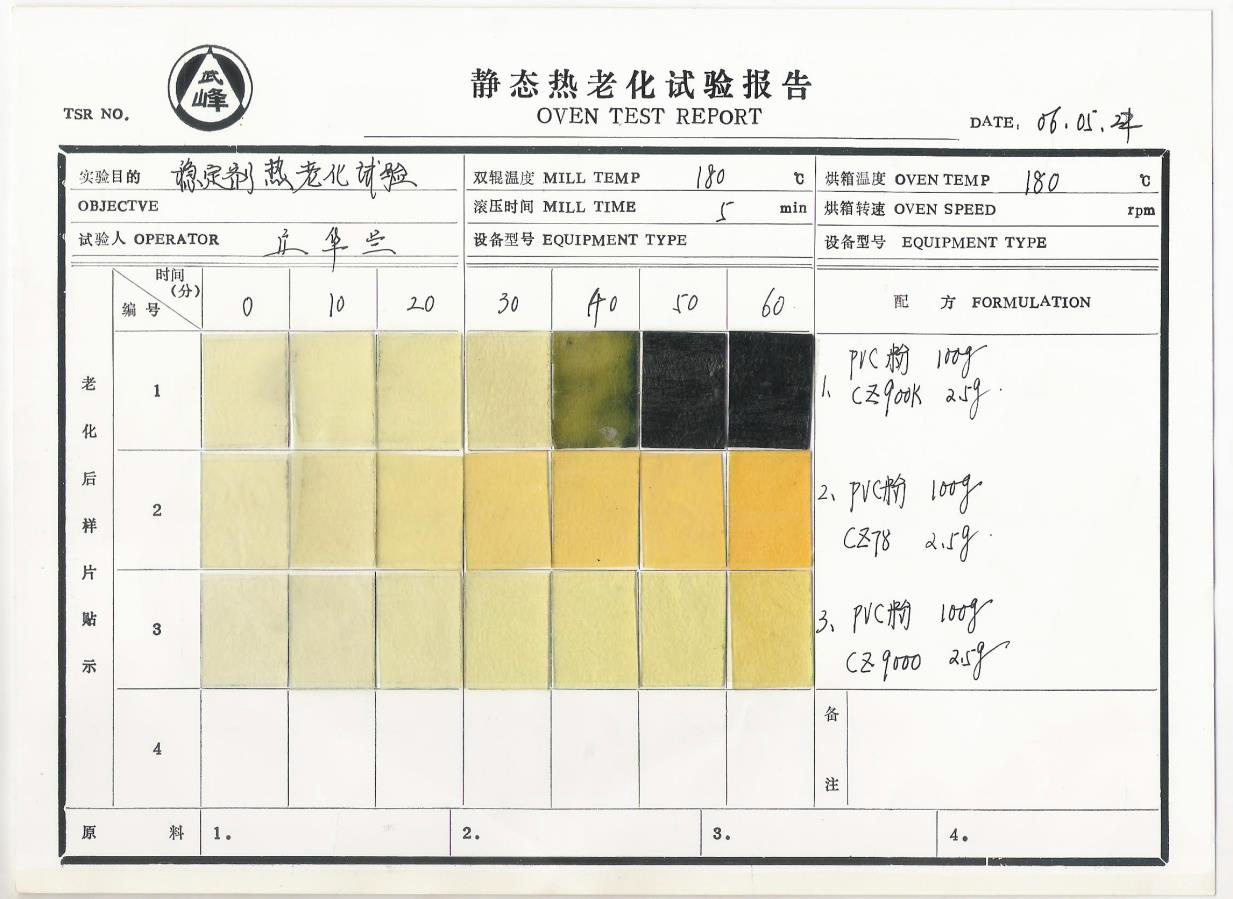

Static thermal stability

Static thermal stability

⚫ Test equipment:

φ160 double roller plasticizer wuxi Rubber and plastic Machinery Factory

Shanghai Luda Experimental Instrument Factory

⚫ sample preparation:

Double roller heating 180±10℃, plasticizing for 5 minutes, the thickness of 1mm film. Cut the slices and place them in a hot oven at 180℃, and take them every 10 minutes.

⚫ Test results: see figure

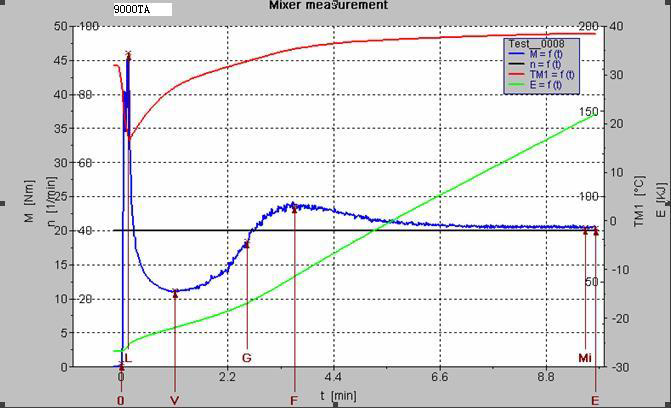

Dynamic thermal stability

⚫ Test equipment:

Haak rheometer Thermo Germany

⚫ Test conditions:

A. Recipe :PVC-100 STAB-2.5

B. Weight: 75g

C. temperature 180 ℃

D. Speed 40 r/m

⚫ Test results: see figure